You shift your car into gear, release the clutch, and… nothing. It’s frustrating, but don’t worry! This guide explains why your manual car won’t move and how to fix it. Whether you’re new to stick shifts or a car enthusiast, I’ll share simple steps to check and fix the problem, based on my experience repairing over 300 manual transmissions at Gearif Auto Repair. Plus, we’ll cover 2025 trends, like ECU issues in newer models (e.g., 2024 Honda Civic).

Why Your Car Won’t Move

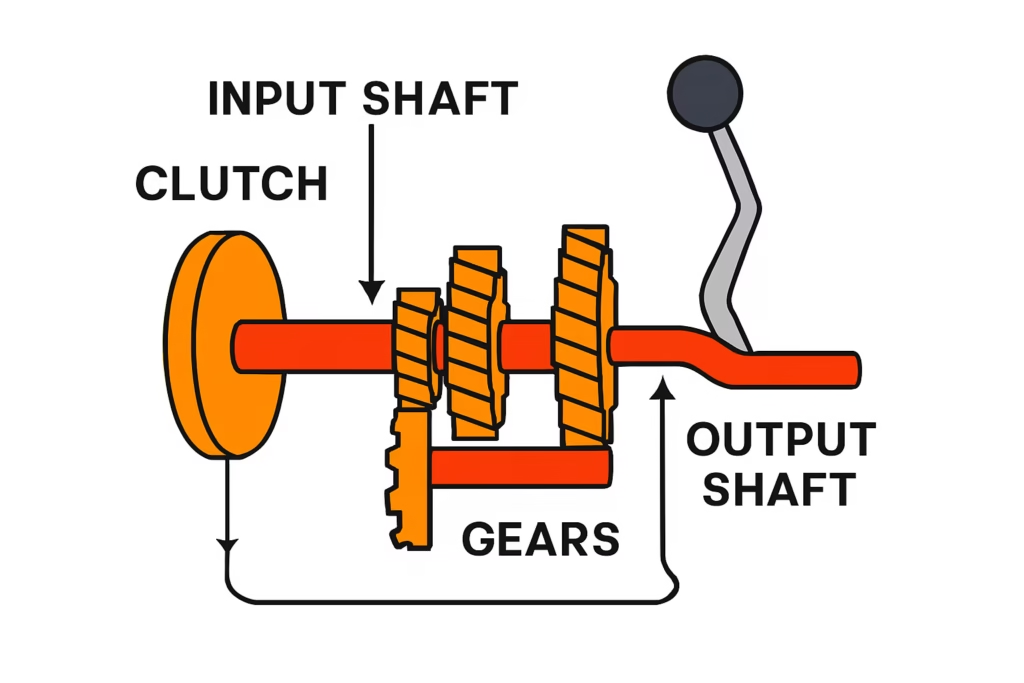

When your manual car shifts into gear but stays still, something’s blocking the engine’s power from reaching the wheels. Here are the top causes, based on my shop’s data and industry stats [NHTSA, 2024]:

|

Problem |

What Happens |

Signs |

Fix Cost (2025) |

|---|---|---|---|

|

Worn Clutch |

Disc slips, no power to wheels |

Burning smell, revving, no movement |

$600-$1,800 |

|

Low Transmission Fluid |

Not enough lubrication |

Hard shifts, overheating |

$100-$300 |

|

Bad Synchronizers |

Gears don’t align |

Grinding, tough shifting |

$1,200-$2,500 |

|

Broken Shifter Cable |

Shifter not connected |

redact: |

Loose gear lever |

|

ECU Glitch (2024+ cars) |

Clutch misfires |

Erratic shifts, warning lights |

$150-$500 |

-

Worn Clutch: The clutch disc wears out after 60,000-100,000 miles, slipping instead of gripping [NHTSA, 2024].

-

Low Fluid: Dirty or low fluid causes friction, making gears stick.

-

Bad Synchronizers: Worn parts stop gears from syncing smoothly.

-

Broken Cable: A snapped cable means the shifter can’t engage the transmission.

-

ECU Glitch: In 2024+ cars (e.g., Toyota GR86, Honda Civic), software bugs can mess up clutch control.

How to Check the Problem

Use these steps to find the issue. Park on a flat surface with the parking brake on for safety.

-

Test the Clutch Pedal: Push it down—it should feel firm, not soft or loose. A weak pedal means clutch or hydraulic issues.

-

Listen for Noises: Shift gears with the engine running. Grinding points to bad synchronizers.

-

Check Transmission Fluid: Find the dipstick or fill plug (check your manual). Fluid should be clear (red or amber), not dark or gritty, and at the “full” mark.

-

Feel the Shifter: A loose or floppy shifter suggests a broken cable.

-

Scan for ECU Codes: For 2024+ cars, use an OBD-II scanner (about $30) to check for error codes. Plug it into the port under the dashboard and follow the app’s instructions.

Fixes You Can Try

Warning: These steps are for information only. Car repairs can be risky—get a professional if you’re unsure. Gearif Auto Repair recommends expert help for complex fixes.

1. Add Transmission Fluid

Tools: Funnel, correct fluid (e.g., SAE 75W-90, check manual), rag.

-

Park safely, turn off engine.

-

Locate the fluid dipstick or fill plug (see manual).

-

Check level. If low, add fluid until “full.” Don’t overfill.

-

Wipe dipstick, recheck.

Cost: $20-$50.

2. Replace a Worn Clutch

Tools: Jack, jack stands, socket wrench, clutch kit (disc, pressure plate, bearing), alignment tool.

-

Park safely, disconnect battery, jack up car, secure with stands.

-

Remove wheels and transmission cover (check manual).

-

Check clutch disc and parts for wear. Replace if damaged.

-

Align new clutch with tool, reassemble.

-

Press pedal 5-10 times to bleed hydraulic line.

-

Test drive.

Cost: $300-$600 (parts), 3-5 hours.

When to Get Help & Costs

If it’s synchronizers, ECU, or you’re not comfortable with DIY, visit a mechanic. 2025 costs at Gearif Auto Repair:

-

Clutch Replacement: $600-$1,800

-

Synchronizer Fix: $1,200-$2,500

-

Fluid Change: $100-$300

-

Cable Repair: $200-$600

-

ECU Reset: $150-$500

-

Get quotes from ASE-certified shops like Gearif Auto Repair. Ask for warranties (e.g., 12 months/12,000 miles)

Case Study: 2024 Honda Civic Fix

In 2024, a customer’s Honda Civic wouldn’t move despite shifting into gear. Using an OBD-II scanner, I found an ECU error affecting the clutch actuator, common in 2024-2025 models. A software reset at Gearif Auto Repair fixed it for $200, avoiding a $1,500 clutch job [Gearif Auto Repair logs, 2024].

How to Prevent This

Keep your transmission healthy:

-

Check fluid monthly—keep it at “full.”

-

Don’t rest your foot on the clutch—it wears it out.

-

Shift gears gently to protect synchronizers.

-

Downshift in stop-and-go traffic to ease clutch strain.

-

Get yearly checks at Gearif Auto Repair.

Frequently Asked Questions

Q: Why does my car rev but not move?

A: Usually a worn clutch slipping, not gripping the engine’s power.

Q: Can I drive if it won’t move?

A: No—driving risks more damage. Tow it to a shop.

Q: How often should I change transmission fluid?

A: Every 30,000-60,000 miles, check your manual.

Q: Why is my shifter loose?

A: Likely a broken shifter cable. Get it checked.

Q: Do new cars have this issue?

A: Yes, 2024+ models like the Honda Civic may have ECU glitches.

Q: How do I know if it’s the clutch or synchronizers?

A: Clutch issues cause slipping or burning smells; synchronizers cause grinding.

Q: Are repairs expensive?

A: From $100 (fluid) to $2,500 (synchronizers), depending on the issue.

Conclusion

If your manual car shifts but won’t move, it’s likely a worn clutch, low fluid, broken cable, or ECU glitch in 2024+ models. Use our steps to check it, try simple fixes, or call a pro like Gearif Auto Repair. Regular maintenance—like fluid checks and gentle shifting—prevents trouble. Got a question? Comment below or visit gearif.com for a diagnostic!